Headlight audit

Your contact

Further informations

VisiLaserWall

Precise laser contours

In the audit, the adjustment accuracy of the production lines is checked. Our VisiLaserWall projects the target contours of the cut-off line precisely onto the projection screen using unique laser technology designed by Visicon. This allows the auditor to conduct a thorough and precise evaluation of the headlight image.

The contours can be defined individually for each vehicle / headlight type.

Discover our components

In addition to the projection boxes, a projection screen is required to display the contours. Using a centralizer the vehicle can be positioned at the audit site to reliably reproduce the test time after time.

Of course we also offer components for conventional 10-meter walls.

-

Projection box

The projection boxes use a green laser to draw the target contours sharply and stably on the projection screen. At a dark audit site, these contours stand out better than the markings on a conventional 10-meter wall.

A second, red setup laser ensures referencing to the optical axis of the headlight.

-

Projection screen

The target contours are displayed individually and automatically for each vehicle or headlight type. The evaluation of the light image is not disturbed by other markings.

-

Software

Our software guides you clearly through the process and enables the definition of individual target contours for each type of headlight. The evaluation is saved in a database and can be done manually or automatically. In addition, the deviation from the target value can be determined and also saved in the database. The connection to an external process control can be realized without any problems.

Our VisiLaserWall+ consists of a conventional VisiLaserWall system combined with a digital camera. This offers further functionalities such as the intensity measurement of the headlight directly at the projection screen, comparable to using a goniometer. Using the VisiLaserWall+, it is possible to analyse headlamps upfront with regards to the test criteria of e.g. the IIHS (Insurance Institute for Highway Safety) rating.

-

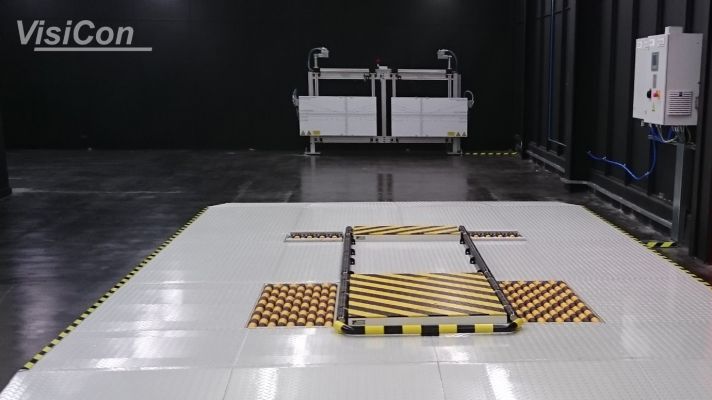

Centralizer

The centering of the vehicle is done pneumatically with roller rails which are applied to the inner side of the tire. Plastic rollers prevent damage to tires and rims. Our centralizers are available in different sizes, can be installed in a pit or with a platform and are equipped with additional drive-in aids on request.

-

Conventional 10-meter wall

When using a conventional 10-meter wall, the vehicle is also positioned in front of the measurement wall using a centralizer. The standardized headlight contours are drawn directly on two measurement panels. These measurement panels can then be positioned either manually or motorized.

-

Headlight audit using a Light Collecting Box

A light audit can also be performed using a special Light Collecting Box: For this purpose, the LCB is equipped with a laser on the bottom side, which is aligned to a reference mark on the headlight. This compensates for manufacturing tolerances during the measurement. The headlight image can then be evaluated either with our software or manually with the help of the built-in scale.

Your contact

Further informations

Address

Gartestrasse 2b

37130 Gleichen-Rittmarshausen, Germany

© Copyright 2024 VisiCon Automatisierungstechnik GmbH

All Rights Reserved